Each tile we offer tells a captivating story, brought to life by skilled craftsmen from different corners of the world, who draw upon generations of expertise. While techniques and materials may vary based on geography, resulting in uniquely stunning products, every journey begins with the preparation of natural materials. This involves extracting raw clay rocks from the earth, soaking them in water, and then working them into a malleable clay. For varied color outcomes, different clays and pigments are chosen, a choice particularly important for our terracotta offerings where glazing is not applied.

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Skilled Artisans

Every tile is an expression of the artisan’s work that day — beautifully imperfect and unique. Glazed and cut to perfection. Each tile is a piece of art in its own right.

Shaped by artisans

Once the clay is ready to be shaped, it is filled into molds to attain the intended shapes. The molds contribute to overall uniformity, yet they are removed before drying and setting, allowing for minor variations in shape as the still-moist clay subtly shifts. If greater shape uniformity is desired, lower-moisture clay can be used, or the molds can be left on for a longer period of time.

Our Story

Air Dried

After molding, the tiles are left to air-dry. This firms up the tiles into a more manageable state, allowing the craftsman to hold and work them moving forward. While reshaping is limited during this stage, slight adjustments like flattening or fine-tuning can still be made. Zellige tiles receive an initial firing here, while others await the glazing process.

Glazed & Unglazed

With the tiles now at the desired shape and consistency, they are ready for glaze. While some tiles will be left unglazed, embracing their natural hue and texture, many are immersed by hand into glaze-filled containers. The craftsmen allow excess glaze to drip away before placing the tiles on racks. Ranging from vibrant primary shades to captivating iridescence, the array of glaze possibilities plays a pivotal role in the distinctive charm of our tile offerings.

Kiln Fired

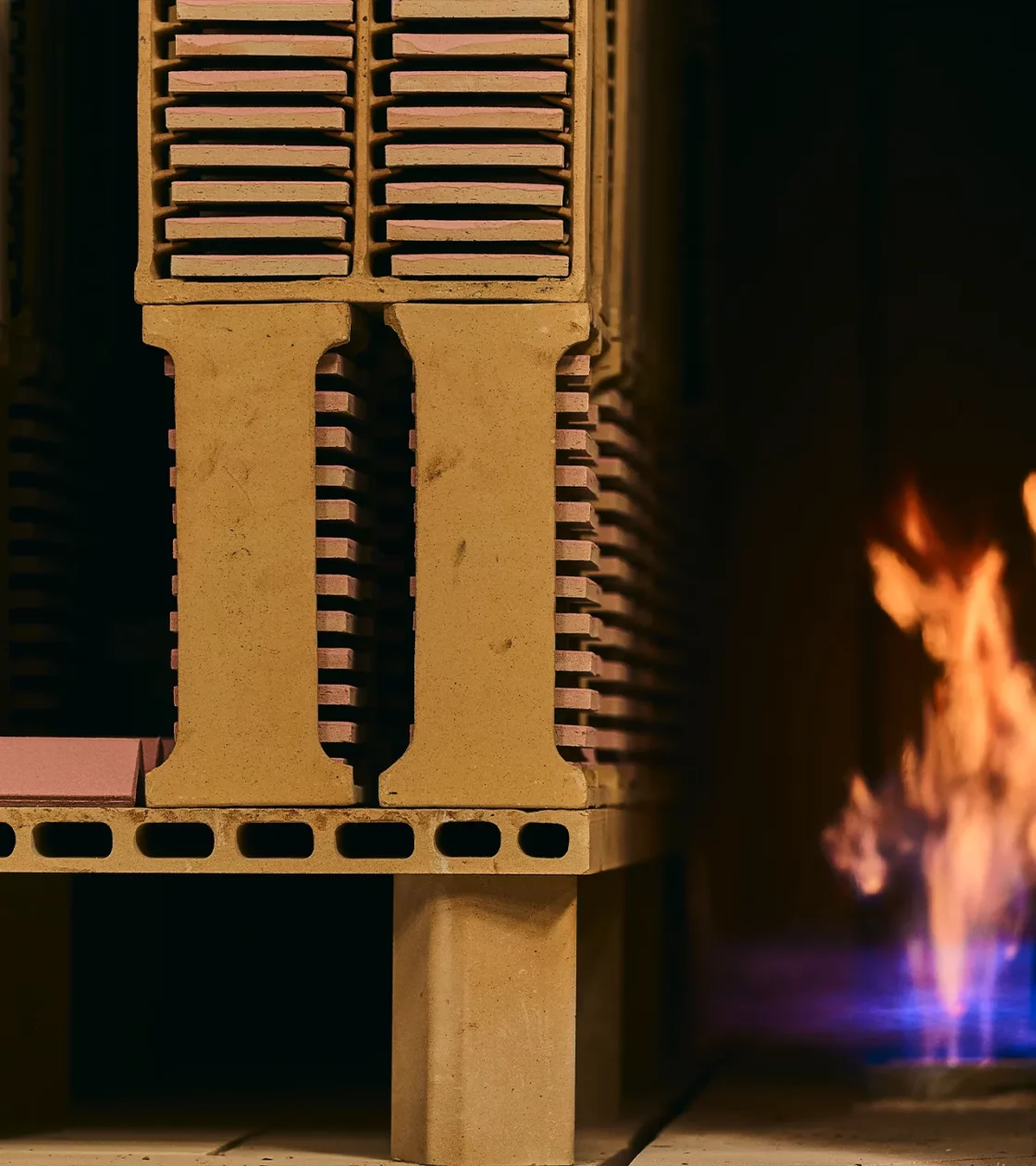

Once glazed, the tiles are loaded into the kiln. Fired at extreme temperature, the clay base solidifies to its ultimate firmness, while the glaze hardens and achieves its final tone. Because some more traditional kilns don’t evenly distribute heat, tiles of the same color can come out looking rather different, amplifying the individuality of each piece. Similarly, any intricacies stemming from the manual glazing process become further accentuated post-firing.

Handmade Tiles

Emerging from the kiln, these beautiful tiles are just about complete and ready to travel around the world to your home. While Zellige tiles will be hand chiseled to a refined shape, others are just subject to a final inspection. What started as just some clay rock in small European or Moroccan town, is now a complete, beautifully handmade tile. Typically exhibiting some degree of imperfection, and often adorned with a vibrant glaze, these products are representative of their handmade nature and the expertise of their incredible creators.

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles

Our tiles